Lifting, pulling and pushing

WEA Guideline D.3.1 on lifting, pulling and pushing. September 2005. Replaces the second edition, October 2004

The WEA Guideline:

- Provides information about working environment rules for manual work.

- Provides guidelines for how to assess the risk when working manually.

- Provides guidelines on how to avoid or prevent the risk of damage to health due to manual work.

- Deals with manual work with objects. Thus, the WEA guideline does not apply to manual work with people or live animals.

Manual work exists in nearly all industries and includes all forms of moving loads which is done using muscle force in whole or in part. This includes, for example, lifting, tipping, carrying, supporting, pulling, pushing, dragging, loading, shovelling and sorting. Manual work can be carried out by one person or a number of people together.

Lifting is defined as handling a load so that it is removed from a surface in whole or in part. Lifting may take place upwards, downwards and in other directions A lift always consists of taking up and putting down, between which, for example, carrying may be involved for a long or short period.

The handling/lift, etc., is manual when it is primarily carried out using muscle force.

The lift is heavy when it involves the risk of injury to health. Lifting loads under approximately 3 kg is normally not assessed as being a heavy lift.

Manual work is the cause of most musculoskeletal injuries. Injuries may be the result of accidents, sudden lifting damage or cumulative wear damage, which occurs after manual work for a long period. Manual work should, therefore, be part of the company’s workplace assessment (WPA) when relevant.

There are big differences in the employees’ physical, knowledge and experience prerequisites for being able to carry out manual work responsibly when it comes to safety and health. The guidelines of the WEA guideline consist of guidance for the majority of active, adult, healthy working people who have received good instructions and have been trained to do manual work.

Special rules and guidelines apply to manual work, which, for example, is carried out by people under 18 years of age and pregnant women. It may also be necessary to consider the increased vulnerability of employees during certain periods; for example, after injury, cumulative wear or illness. The WEA guideline does not include guidelines for employees with increased vulnerability.

1. Strain and the risk of injury

Manual work may cause injury to the body’s joints, muscles, tendons, circulation and nerves. Back injuries are especially common. It is, of course, major, frequent, repeated and long-term stress on the body that can result in injury.

The risk of injury is related to:

- The weight that is to be moved

- The force that is used

- The method that is used; for example, if lifting, carrying, dragging, pulling or pushing is involved

- How the body is used, including the working position and movements, direction of force and acceleration

- Whether suitable technical aids are used, which provide relief for some or all of the moving

- The planning and arrangements for the work; for example, how often and how long the manual work takes place and whether there are suitable breaks for recovery.

There is an especially great risk of injury:

- When the strain is unexpected

- In case of unaccustomed work

- When you are exposed to vibrations or work while bent forward before starting lifting work.

A suitable amount of motion, muscle work and rest (recovery) is required in order to keep the body strong and functional, and maintain good condition. It is recommended to warm up before starting manual work.

Injury due to manual work may, among other things, be in the form of a slipped disc, pain in the back, osteoarthritis, non-specific back problems, broken bones and sprains, as well as muscle and tendon disorders in the back, back of the neck, shoulders, arms and legs. Injuries will often first prevent carrying out manual work, but may also result in long-term disorders, disabilities and loss of working capacity if measures are not taken.

2. Rules about manual work

The rules about manual work apply to all work that is covered by the Danish Working Environment Act, including work in private homes and work that is carried out by the employer himself or herself.

Work with manual handling must be planned and arranged so that it can be carried out responsibly with regard to safety and health.

Manual work that may involve risks to safety or health must be avoided. If this is not possible, effective measures must be taken to prevent the risks.

The nature of the load must be considered.

The physical effort that is required at the place of work and working conditions in general must also be considered.

As far as possible, adjustments must be made between the load’s weight, form, surface, placement before and after handling and the number of times it is moved.

Suitable technical aids must be used when possible and appropriate, and always when manual work involves danger to health.

The load must be packaged if this is necessary for carrying out the work without risk. The packaging must be secure.

Stacking must be able to take place in a safe working position and without the risk of the loads slipping.

As far as possible, transport routes must be cleared of obstructive objects and must not be slippery. As far as possible, transport routes must have sufficient clearance height and width so that work can be carried out in a fully upright position.

Transport routes must be well lit. There must be sufficient light for an employee to get their bearings and recognise people, objects and any unevenness of the surface.

Employees who carry out continuous manual tasks must have suitable breaks in the form of other work or rest. The same is the case for manual work in especially high or low temperatures.

Unnecessary physical strain and unsuitable working positions or movements must be avoided. The strain during work must be minor enough that it is reasonable, taking technical developments into account. Determined limits must be complied with.

The employer must ensure that employees are provided with safety footwear if there is a risk of foot injury, and gloves if there is a risk of hand injury. The employer must ensure that the required personal protective equipment is available if the manual transport involves contact with objects that can cause damage; for example, sharp, hot or cold objects and materials, biological agents and dust. The employees are obligated to use the protective equipment that has been provided.

The employer must ensure that manual work is planned, arranged and carried out responsibly in compliance with the rules.

The employer must also ensure that employees who carry out manual work are instructed on how to carry out the work responsibly. Employees must have all information that is necessary for carrying out the work. They must, for example, be informed about the weight of loads that are to be lifted, pulled or pushed, or handled in another way.

The employee must have completed suitable training and instruction on good working techniques and correct use of technical aids if the work might involve risks to safety and health.

3. Assessment of lifting

The basis for assessing lifting is the weight of the load and its distance from the back during lifting (the distance from the torso). The assessment form can be used to support the assessment.

When assessing, a number of other factors must also be considered, which individually and especially when combined, may worsen the strain. These factors are described in section 6 of this WEA guide.

3.1. Weight and distance from the torso

The distance from the torso (R) multiplied by the weight of the load provides an expression of the outer strain on the back.

Whether the person performing the lift is only strained by part of the load’s weight must be considered. For example, this may be the case when the load is tipped over on one end or when more people are involved in the lifting.

The assessment form provides guidelines for when the strain is regarded as damaging to health and therefore measures must be taken.

The distance from the torso (R) is shown in the illustration. (R) is the horizontal distance between the load’s line of gravity and the lifter’s lower back - more specifically, a point in the middle of the lowest vertebrae in the lumbar region. For people with a normal weight, the point is located approximately in the middle of the body at the level of the iliac crest.

The line of gravity is the vertical line that goes through the load’s centre of gravity. It normally goes through the middle between the gripping points on the load.

When tipping a load onto one of its ends and when lifting is carried out by two people, the distance from the torso is from the lifter’s lower back to the line through the gripping points on the load.

The greatest distance from the torso while lifting must be used when assessing according to the form on page 9. The greatest distance from the torso is often at the beginning or at the end of the lift (when putting it down).

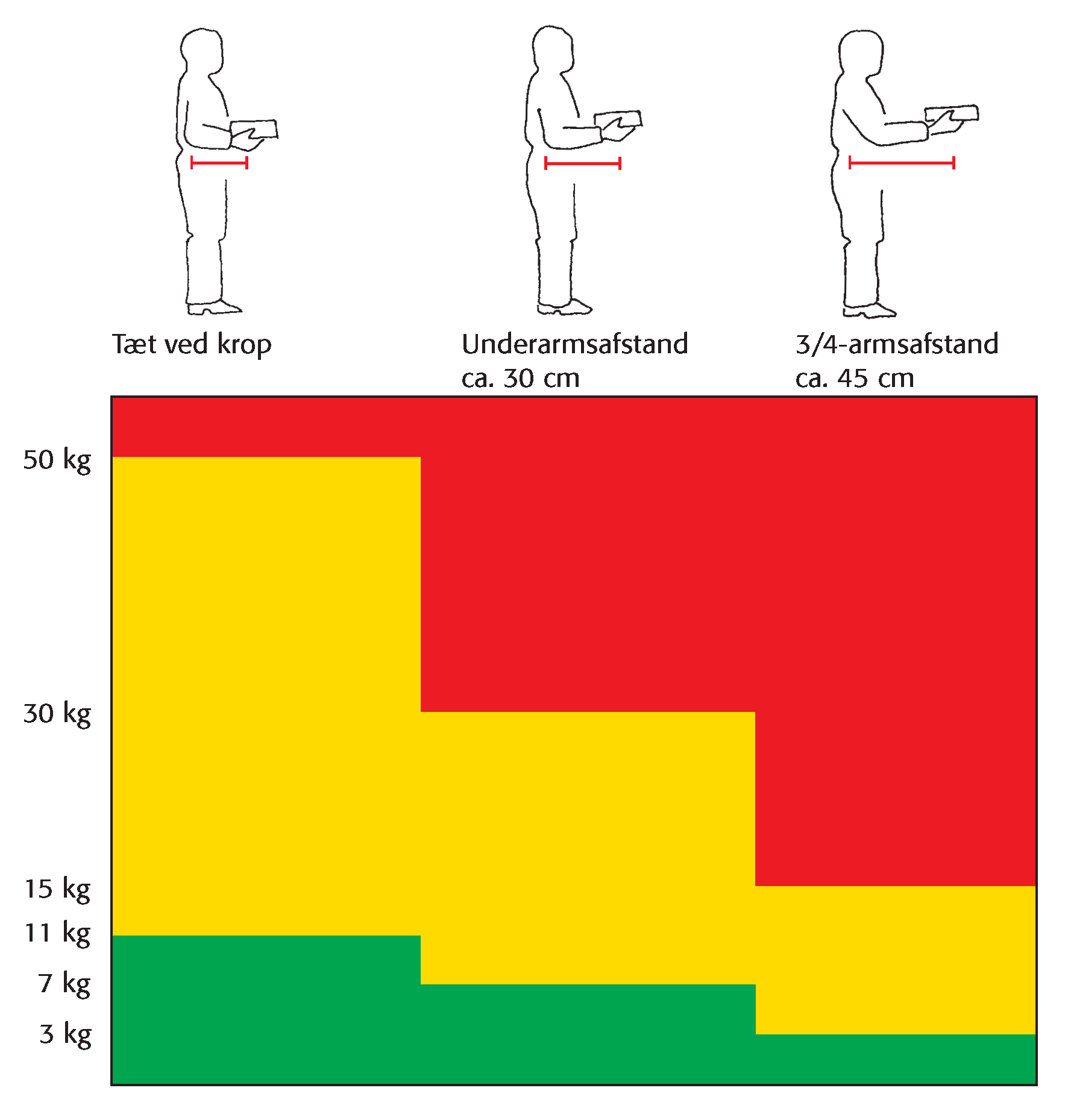

A distinction is made between three distances from the torso.

- Lifting close to the body*)

- Lifting to underarm distance (approx. 30 cm)

- Lifting to 3/4 arm distance (approx. 45 cm)

*) A load is rarely lifted close to the body, except when carrying straps and other aids are used.

Lifting that takes place at a greater distance from the back than 3/4 of an arm’s distance is not covered by the form. Such lifts will normally run a risk of damage to health and should always be assessed separately.

Red area:

Lifting in the red area is regarded as being dangerous to health. Measures must be taken immediately to prevent the risk.

Yellow area:

Lifting in the yellow area means that a more detailed assessment must be made of the other factors (see later) to determine whether they worsen the strain, in which case the lift may be regarded as being dangerous to health.

In the upper level of the yellow area, the lift is only acceptable if it is carried out in optimal conditions. This means that the entire lift takes place in the middle in front of the body, between mid-thigh and elbow level, that the load has been calculated for handling, that at least two minutes pass between lifts, that no carrying is involved, that the foothold is stable and that the climate is suitable.

In the middle part of the yellow area, the number and degree of factors that worsen the situation is crucial for whether the lift may result in damage to health.

If the lifting strain is close to the green area, there will normally be a number of worsening factors present before the lift is regarded as damaging to health. In some cases, a single factor, for example, the working position, may be so stressful that the lift at the bottom of the yellow area may result in damage to health.

Green area:

Lifting in the green area is normally not damaging to health due to weight and distance from the torso.

However, there may be other factors, which in themselves are so stressful that the work may damage health. These factors include, for example, a high frequency of lifting and a large total physiological strain. In case of repeated lifting in the green area, it will most often be relevant to use another assessment model, for example, assessment of monotonous, repetitive work (EGA) or assessment of working positions and movements.

3.2. Overall assessment

An overall assessment of the work must always be prepared before measures are taken. All factors must be included in an overall assessment.

The factors that must be included in the assessment are:

- Weight, distance from the torso and the other factors (see below), which result in the strain.

- Whether lifting and carrying work is the main function in the day-to-day work of the employee or whether lifting is only done occasionally, followed by periods during which the body can recover.

4. Assessment of the total weight

In case of work that involves a lot of lifting per working day, the total weight must be considered in the assessment of whether the work may damage health.

The assessment is based on the combined weight of the loads.

If the individual loads are lifted a number of times, the load’s weight must be multiplied by the number of times it is lifted.

Measures must be taken for lifting work if the total weight per employee per day exceeds the guidelines below:

- Approximately 10 tonnes per day for lifting close to the body

- Approximately 6 tonnes per day for lifting at underarm distance

- Approximately 3 tonnes per day for lifting at 3/4 of an arm’s distance.

The figures for the total weight per day must be reduced if there are factors that worsen the situation, see section 6.

If the individual lifts loads with more than one distance from the torso, a calculation is made on what the percentage is of the 10, 6 and 3 tonnes that are lifted for each distance from the torso. The figures are added together. If the combined percentage of stress exceeds 100 per cent, measures must be taken. The percentage of stress must be correspondingly reduced if there are worsening factors when lifting.

Example of calculating the percentage of risk:

The following is lifted:

1 tonne close to the body = 10 percent

3 tonnes at underarm distance = 50 percent

2 tonnes at 3/4 of an arm’s distance = 67 percent

Total = 127 percent

The weights stated are guidelines for the majority of active, adult, healthy working people on the condition that the lifting otherwise takes place in optimal conditions.

Lifting in the green area is not included in the total weight. Therefore, the total weight is not used as the basis for the assessment if most of the lifts are within the green area. This work is assessed based on other assessment models, for example, assessment of EGA, assessment of working positions and working movements or based on an overall assessment of the work in which all factors are considered.

5. Assessment of carrying

Carrying loads should be avoided as much as possible. If carrying cannot be avoided, the work must be assessed. These guidelines may be used to assess carrying work.

The muscles work statically and the circulation is strained when a load is carried (held lifted for a long time). Therefore, how long carrying takes place and what the working position is are crucial for the assessment of the risk to health.

It is also significant whether the person who is carrying stands still or moves with the load. When the person walks, the weight shifts from side to side while the body twists. There is also a risk of slipping or stumbling with the load.

When the load is carried while walking; that is, for a distance of more than about 2 m, the form on page 9 cannot be used directly for assessing the strain, but the maximum weight for the yellow area must be reduced significantly. The boundary between the red and yellow areas would then be:

- Approximately 20 kg close to the body

- Approximately 12 kg at underarm distance

- Approximately 6 kg at 3/4 of an arm’s distance.

The distance from the torso when carrying will often be less than the lift itself.

A prerequisite for the guidelines for weight limits is that the other factors do not worsen the strain.

The length and condition of the transport route must be considered. Carrying on stairs is especially stressful and also involves the risk of unexpected strains if the person stumbles. When carrying loads with a weight that is within the form’s yellow area (with the boundary between the red and yellow areas mentioned above), the transport route should be no more than approximately 20 m on an even surface. An ordinary step in the transport route is comparable to a carrying distance of approximately 1 m.

Transport routes where carrying is carried out must be even, cleared and well lit. The surface must be stable and must not be slippery.

When the carrying work lasts a long time or is repeated a number of times during a working day, these are considered to be worsening factors. It is therefore important to limit the weight as much as possible for work involving carrying working equipment, tools, etc. The presence of other factors must also be included in the assessment. Carrying may involve long-lasting static strain and no green area can be indicated for long-lasting carrying work that corresponds to the form.

6. Assessment of other factors when lifting and carrying

When assessing lifting work according to the form or the guidelines that are mentioned in the section on assessing the total weight and assessment of carrying, the other factors that can worsen the strain must be considered.

The other factors are divided into four main groups:

- The nature of the load

- The physical effort

- The nature of the place of work

- Other working conditions.

6.1. The nature of the load

It is a worsening factor if:

- The load has a size or form that results in an unsuitable working position for arms or the back, or limits vision.

- The load is unwieldy or difficult to get a hold of, for example, if it is slippery, hot, cold or lacks hand grips.

- The load or packaging can easily break.

- The load is unstable or the content can slip out of place.

- The load may cause injury if you hold onto it or are hit by it, for example because it has sharp points, sharp edges, is very hot, cold or is caustic.

- The load is placed so that it cannot be lifted close to and in the middle in front of the body with suitable working positions for the back, arms and legs.

6.2. The physical effort

Working positions, movements, energy conversion and time constrains in connection with lifting and carrying work have significance for the physical effort and for the risk of sudden injury.

Thus, they are worsening factors if:

- The lift must take place crookedly/asymmetrically in relation to the body.

- The lift is started with a jolt or is suddenly stopped.

- The lifting work takes place at a fast tempo.

- The back twists, is bent forward or to the side, or especially if the back is bent forward and twisted at the same time. The strain will increase with the degree of bending forward, twisting and duration, as well as when the load is reached out to.

- The arms are raised, especially if the hands are raised to or above shoulder height.

- Lifting is done from low heights. In this case, it is not just the load that is lifted, but the entire body.

- Lifting is done from the side or using one hand. The back is strained by doing so approximately twice as much as lifting in the middle in front of the body with two hands.

- The load must be put down precisely. Here, the duration of the lift and thus the strain increases.

Stressful lifting work is carried out best in a stable, standing position where the body’s large muscles can work. It is therefore a worsening factor if stressful lifting work is carried out in sitting, squatting, kneeling or similar positions.

6.3. The nature of the place of work

Worsening factors occur in case of:

- Restricted space conditions.

- Insufficient space at a height

- Unsuitable arrangements, for example, unsuitable placement of machines and equipment with regard to transport and flow of items.

- Unsuitable placement of loads.

- Surfaces that are unstable, uneven, slippery, too hard or too soft, sloping or with different levels. Carrying on stairs or on ladders must be avoided as far as possible.

- Cold, humidity, draughts, wind or high heat.

- Poor lighting or poor visibility conditions. The risk of stumbling or of grasping the load incorrectly will be increased.

6.4. Other working conditions

Worsening factors may occur in case of:

- Frequent, repeated lifts or long-lasting carrying. The strain may be damaging to health even if the individual lift is not. Important factors are, therefore, how frequently lifting is done, how long the individual lift/carrying lasts, whether the loads are lifted upward, downward, toward or away from the body and whether they are carried for long distances. At the same time, it is crucial to know how much is lifted in total during a working day, how much of the working day is spent on lifting, whether the lifting work is continuous and whether there are sufficient periods for resting and recovering.

- Risk of unexpected strain. This is an important factor because unexpected strain may lead to acute injury or contribute to cumulative wear in the long term.

Unexpected strain may, for example, occur when lifting loads with an unknown weight, loads that are stuck or due to poor foothold conditions while lifting.

There may also be a risk of unexpected strain when a number of people lift together, for example, if everyone does not lift or put down the load at the same time or if one person loses his or her grip while lifting. The load’s centre of gravity, individual differences between the people who are lifting together and differences of working techniques also have significance for how much the individual is strained during lifting. When two people lift together, the strain can vary. The weight of the load when two people are lifting should, therefore, not be more than 70 per cent of what the individual person could lift. This means that two people - close to their bodies and in otherwise completely optimal conditions - cannot lift 100 kg together, but 70 kg at the most.

Lifting done by two or more people cannot replace the use of appropriate technical aids.

Other factors that might increase the risk of damage to health are:

- Vibrations from manual tools, machines and vehicles. If, for example, the back is subjected to vibrations when driving a forklift truck, the risk of subsequent damage due to lifting is increased.

- Lifting by others, for example at an assembly line, or by a machine at a regular pace.

- Poor psychosocial working environment or a heavy workload where chances are taken.

- Lifting work carried out with lack of routine and unsuitable working techniques.

- Lifting/carrying that is part of work that otherwise strains the back.

7. Measures to be taken when lifting and carrying

Lifting and carrying which may result in damage to health must be avoided through planning and arranging the work responsibly. The nature of the load and the other factors mentioned above must be considered.

The necessary measures must be taken before carrying out the work.

When planning and arranging the work, an effort must be made to ensure that:

- Appropriate technical aids are used.

- The weight of the load that is to be handled is limited and that it is easy to get a hold of and is stable.

- The shape or size of the load does not hinder visibility and working using suitable working positions and movements.

- The place of work has been set up suitably.

- There is enough time for muscles and joints to recover between each lift and every time something is carried.

- Continuous work is avoided by varying it with other work or breaks.

- The total weight that is lifted is as light as possible.

- The lift/carrying takes place at a slow tempo, but that it also does not last long.

- The fact that unexpected situations with especially stressful factors may occur is considered.

7.1. Technical aids

Technical aids:

- Must be available in sufficient numbers and located appropriately with regard to the work.

- Must be designed according to ergonomic principles.

- Must be suitable for the load, the place of work and the user so that the aid removes or reduces the strain without causing other risks to the health of the user.

- Must be properly maintained. A set procedure for maintenance can ensure this.

7.2. The nature of the set-up of the place of work

The place of work must, as far as possible, be suitable with regard to the physical strain of the work. This applies to all areas of the place of work that have significance for carrying out lifting and carrying work, for example, placement in the work area, and fixed and loose equipment. It must also be ensured that:

- There are good spatial conditions for carrying out the work and for equipment and technical aids, and that there is good visibility.

- The equipment is designed suitably for the work and for the person who is to use it. When doing work that does not require the use of force, it is often an advantage that the equipment is designed so that it makes it possible to switch between standing and sitting.

- The equipment and technical aids are designed so that the distance from the torso is as short as possible when the load is lifted and put down.

- The working height can be adjusted so that work can be done using good working positions. This means that the load must be close to the body, between the mid-thigh and elbow level, so twisting and bending the back is not required.

- Lifting from the side and lifting and carrying using one hand is avoided or limited.

- The surface is even, stable, not slippery, and shock absorbing, as well as without obstructive objects.

- The lighting is appropriate with regard to the type of work, the location of the place of work and the room in general.

- The temperature, cold/hot radiation, air speed and air humidity are suitable.

7.3. Other measures

Carrying straps can give a more centred and symmetric weight distribution of the load on the body. The carrying straps may thus reduce the physical effort of lifting and carrying work and provide a more secure and stable grip on the load.

Work clothes must not prevent suitable working positions and movements and must be able to be adjusted to climatic conditions and the level of physical activity.

Personal protective equipment must be suitably designed with regard to freedom of movement and weight strain.

8. Assessment of pulling and pushing, etc.

Pulling and pushing using different vehicular technical aids is normally a suitable measure for lifting and carrying heavy loads or many loads.

Pulling and pushing takes place most frequently in the transportation, building and construction, and service industries. Pulling and pushing using vehicular technical aids may involve a risk of injury to health, especially in the shoulders, but also of accidents, for example, the risk of being crushed, run over, stumbling or falling.

Pulling and pushing also occurs in many other situations. For example:

- When starting to lift when the load is pulled forward.

- When moving objects that are in the way, for example, furniture while cleaning.

- When pulling out nails from boards or boards from a pile of boards.

- When dragging/sliding sacks or loads across a surface.

- In case of loads that are hung up on a conveyor system.

- When tipping barrels.

The strain in these situations does not only depend on the weight of the objects, but also the friction on the surface and any tension/friction between the items.

Pulling and pushing is manual handling and must be assessed with regard to the risk of health-damaging strain. Legislation requires that suitable technical aids must be used when possible and appropriate, and always when manual transport involves danger to safety or health.

8.1. Assessment of pulling and pushing using technical aids

The following elements must be included in the assessment:

- The design of the transport equipment

- The maintenance of the transport equipment

- The nature of the surface

- Space conditions

- Visibility conditions

- Unexpected events

- Weight and stability of the equipment and load

- Speed and changes of direction

- Working method (pulling/pushing, load in front/in back of the person)

- Working positions and working movements

- The frequency and duration of the work.

8.1.1. The design of the transport equipment

There are many different types of manual transport equipment with one, two or four wheels. The most common types are wheel barrows, sack trucks, lifting trucks, wire mesh cages, wheeled containers, small dollies, pallet lifter and trolleys. In addition, there are a number of self-driving technical aids, which are suitable solutions in a number of situations.

The transport equipment must be suitable for the loads that are to be transported and the place where transport is to take place. Unloading and loading must be able to take place in accordance with the guidelines for lifting.

The wheel diameter, wheel width, firm or air-filled tyres and the possibility for turnable/fixed direction wheels must be assessed with regard to the surface, space conditions and other factors. Small wheels have a perfect surface as a prerequisite. Wheels on rolling pallets and wheeled containers should have a diameter of at least 10 cm.

The hand grips must be suitably place and formed in relation to the working method and the person. When pushing forward, a suitable hand grip height corresponds to approximately 70 per cent of the person’s shoulder height or a height of approximately 100 cm with the possibility of adjusting approximately 10 cm up and down. When pulling backward with the transport trolley in front of the body, lower placement will often be most suitable. When turning around and turning, it may be best to grab a hold a bit higher. It is recommended to switch between different heights of hand grips.

The width of steering handles for two hands should be approximately 45 cm and the thickness 3-4 cm. Steering handles must be placed so that legs and arms do not bump against the trolley or the load when walking with the trolley.

8.1.2. Maintenance of the transport equipment

The wheels must be maintained so that the friction is low. Poorly maintained wheels may result in a crooked pulling direction and be a major strain on the body and arms.

Defective technical aids also cause a risk of accidents. This may be avoided if, for example, there is a standard procedure for inspecting and maintaining the technical transport aids.

8.1.3. The nature of the surface

Surfaces on which pulling and pushing is to take place must, as far as possible, have limited rolling resistance and be stable, even and free of obstructing objects and clutter. It may be possible to compensate for small unevenness with large, air-filled wheels. It may be necessary to change the surfacing if the transport takes place on an uneven or soft surface, such as gravel. It may be possible to use a suitable self-driving technical aid with large wheels.

The surface must ensure good footing and be stable. The friction between footgear and the surface is crucial for how much pushing/pulling can be performed.

If a manual pushing or pulling technical aid is used on a sloping surface, it must be equipped with a brake to the extent that is necessary.

Pushing and pulling on a sloping surface increases the strain. In case of a sloping surface, it will quite often be necessary to replace the manual technical aid with a self-driving technical aid.

8.1.4. Space conditions

There must be sufficient space for loaded transport equipment to be positioned, so that the equipment is not encumbered. If the equipment is stuck, it causes unnecessary physical strain to get it going. Lack of space may also result in a risk of crushing and falling.

It must be possible to work in suitable working positions when pulling and pushing.

There must be sufficient free space to avoid damage to hands when manoeuvering with the technical aid. There must also be sufficient space so that manoeuvering does not result in unnecessary strain.

8.1.5. Visibility conditions

Transport equipment and loads must not limit visibility in the direction of movement. It must be ensured that there is good visibility while working in suitable working positions. There must be sufficient lighting so that the surface and space conditions, as well as any unevenness and obstacles, are visible.

8.1.6. Unexpected events

Unexpected events, such as sudden braking or a sudden change of direction or acceleration may, for example, occur in connection with unsuitable surfaces, clutter, dirt that can get into the wheels, poor lighting conditions and influences from outside.

8.1.7. Weight and stability of the equipment and load

The weight of the equipment and load have great significance for the force* that must be used to start, maintain, stop and turn with a load. A self-driving technical aid will normally be what is the most suitable for large and heavy loads. No specific weight limit can be given for when a self-driving transport aid is required because the other factors are also of major significance.

* According to Newton’s second law of gravity, the net force is equated to the product of the mass times the acceleration. In addition to this, the friction in wheels and resistance from the surface may also increase with increasing weight. The Danish Working Environment Authority’s guidelines for pushing and pulling, where the starting force should not exceed 400 N and the maintenance force should not exceed 200 N is no longer used in practice because the measurement uncertainty is too great in measurements “in the field”. These values do, however, form the basis for the guidelines for pulling and pushing, among other things, on sloping surfaces where they can be based on calculations. These days, the risk assessment is carried out in relation to an overall assessment. A risk assessment cannot be carried out based on only one factor.

Practical experience indicates that lifting trucks, wheeled containers, wire mesh cages, etc. with a total weight (vehicle plus any pallet plus load) of less than 200 kg will rarely cause problems for short-term transport on even, horizontal, drivable surfaces and with good space conditions. If the total weight is between 200 and 500 kg, it may be critical, depending on the other factors present, while total weights of 500 kg and above will almost always be problematic.

When pushing and pulling on a sloping surface, the effect of gravity is significant for the force that must be used: The greater the incline, the heavier the load, and thus greater force must be used, resulting in greater risks to health. For an increase of, for example 1:4, measurements have shown that a total weight of 40 kg can be critical.

The load must be packed in a stable manner so that it does not tip over or slip out of place during transport.

8.1.8. Speed and changes of direction

Starting, braking and changes of direction result in large force effects when pulling and pushing. It may be necessary to use self-driving equipment when work requires frequent starting, braking and changes of direction. Wheels and hand grips may also have great significance in case of frequent changes of direction.

The risk of sudden overload when changing direction and braking, as well as in case of accidents, for example collisions, is especially great for heavy loads on light vehicles without brakes and especially if the surface slopes. This is because the vehicle goes too fast and is therefore difficult to stop.

8.1.9. Working method

The strain on the back, shoulders and arms depends on the working method used. Working positions and force directions are different. This must be included in the assessment.

The working method cannot always be freely chosen, but will, among other things, depend on:

- The design of the technical aid.

- The placement of the load at the start of transport.

- Whether it is possible to use one’s one body weight (by pushing forward) or whether there is a need to reduce the friction in wheels or with the surface (pulling backward).

Some technical aids are only intended for pushing - others are only for pulling. The aid may be in front or behind the person. When using the technical aid, one or more functions may be automated, for example, adjustment of height or progress.

Finally, pulling and pushing may occur with conveyor systems, where the load is suspended, possibly above head level, and is moved forward by pushing directly on the load or by using a drawbar or similar tool.

When pulling and pushing loads that are suspended a conveyor above shoulder level, you use your own body weight using backward pulling, but the friction can be reduced by pushing forward. However, an element of lifting can very easily be involved in the work, which increases the risk of back and shoulder injury.

8.1.10. Working positions and movements

When assessing the strain on the body when pulling and pushing, the outer force influences from the work and the force influences from the position of the body must be compared.

Often, shoulder strain is critical; for example, due to work in an extreme position or due to the direction of the force.

In a number of situations, the working position and the body’s own weight are used to ease the work; for example, when leaning forward while pushing a load forward or when pulling a load behind the body.

The body’s inclined working position can therefore be used to assess how much force must be used. With inclined working positions there is a risk of sliding, stumbling, falling and losing control of the aid. A inclined body position will often be a sign that the force required is too great, and that, for example, it may be appropriate to use a self-driving technical aid.

8.1.11. The frequency and duration of the work

When pulling and pushing, there may be frequent starting and long-lasting work tasks that cause static strain. This gives a risk of health damage in both the short term and the long term. Continuous manual transport must be interrupted by other work, or breaks must be incorporated for recovery.

9. Measures to be taken when pulling and pushing

In order to prevent damage to health, the technical aids that are made available must be suitable for the person, the place of work and the task.

The place of work must be suitably arranged both with regard to surface and space conditions.

If the responsibility is divided among a number of employers; for example, a haulier and a shop owner, the law requires them to cooperate on solving any problems.

Technical aids must be loaded responsibly so that the load is stable and does not slide during transport. The load must not be too heavy and not limit visibility of the transport route.

The technical aids must be self-driven as needed.

9.1. Dragging of loads

The dragging of loads is much like pulling and pushing and may be assessed according to the same criteria. Friction on the surface is an important factor, together with the working position. The friction can often be reduced by using, for example, a slippery intermediate layer, castors, rollers or technical aids.

9.2. Instructions

Employees who perform lifting and carrying work, pulling and pushing, and other forms of manual handling, must have had prior instruction and training in the use of technical aids and good working techniques. The employees must follow the instructions.

Instructions on working techniques must include all information that is necessary for the work to be carried out responsibly. The employees must, when possible, be informed about the weight of the loads that are to be handled.

Instructions on working techniques should be given as theory and as a test in the actual working conditions. When working when there is a risk of unexpected strain, instructions and training must include suitable behaviour in such situations.

The instructions must be repeated as needed.

The company’s safety organisation or the employees must participate in planning the work regarding safety and health.

Jens Andersen